How 24hr Media can Save You Time, Stress, and Money.

How 24hr Media can Save You Time, Stress, and Money.

Blog Article

The 9-Minute Rule for 24hr Media

Table of Contents24hr Media for Beginners24hr Media Things To Know Before You Get This24hr Media - QuestionsThe 10-Minute Rule for 24hr MediaSee This Report about 24hr Media

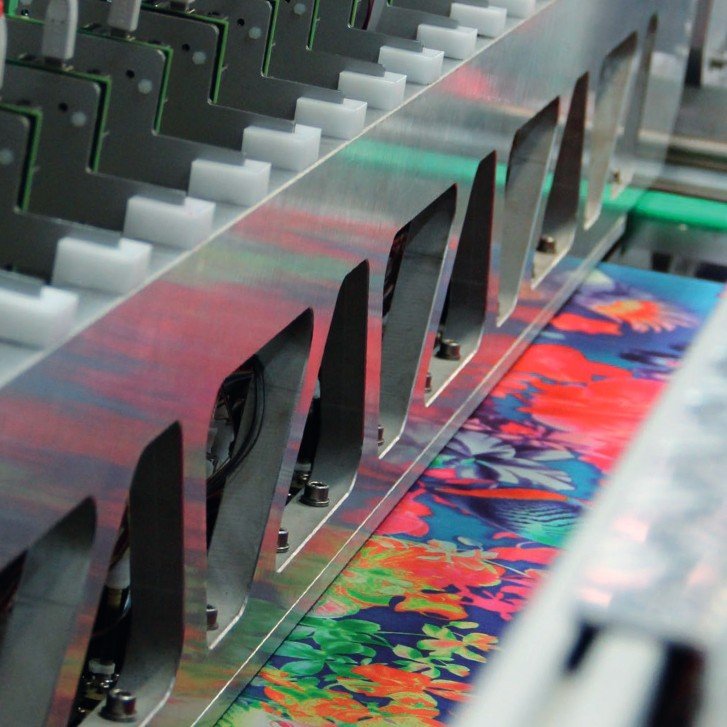

Offset, gravure printing and flexography are one of the most common kinds of conventional printing in the product packaging room and each includes transferring the picture from a plate to the surface. To do this, initially the plate requires to be created, and it is the creation of these plates that take time, and set you back cash.According to PMMI, electronic printing enables brands and producers to respond swiftly to customer needs while enhancing the supply chain, decreasing warehousing cost and waste, and enjoying faster time to market. That all audios wonderful, however how does this innovation do all that? The significant differentiator of these innovations is that there are no set-up costs and no plates with digital printing.

According to Wikipedia, the greatest distinction between digital printing and typical approaches such as lithography, flexography, gravure, or letterpress is that there is no requirement to change printing plates in digital printing, whereas in these analog printing approaches the plates are consistently changed. This leads to quicker turn-around time and lowers expense when making use of digital printing.

Quick manufacturing implies obtaining your item to market much faster. It also suggests it's much easier and faster to make changes in the future, when you change a dish, include a SKU, or produce seasonal product packaging. Digital printing is highly versatile, so it's simple to make adjustments to the package style rapidly. Everything goes back to home plates.

24hr Media - Truths

With standard printing approaches, short-run printing is just not feasible. Because an excellent style can make or damage your item, digital printing constantly produces premium, clear and vibrant graphics each time.

Filling ... Are you acquainted with the advantages of digital printing? Keep reading to understand when electronic printing can be the most effective feasible option for your service. Do you recognize why electronic printing has ended up being the favorite selection of some organizations? Both balanced out and digital printing have their place in the printing industry.

In this post, we will certainly review the advantages of electronic printing to help you much better recognize if electronic printing is just what you need. Basically - electronic printing prints material directly onto the paper. It removes some steps required in balanced out printing, like creating steel plates. Inkjet printers utilize small nozzles to spray beads of ink onto the substrate.

The Single Strategy To Use For 24hr Media

As electronic printing frequently develops, it uses extra possibilities and higher output top quality every day. In some instances, the print quality can be as high as to offset printing.

For offset printing, if any type of error goes unnoticed before producing home plates, there will certainly be a high expense of developing a new one. With electronic printing, this is not the instance (Custom Printed Packaging). Everybody constantly hopes there will certainly be no blunders, understanding the cost of fixing them if they take place is constantly a great idea.

This suggests every piece will certainly look the exact same, so the opportunity you will require to throw out any one of them since of disparities is reduced. Because a proofing example is printed on the same maker as the product itself, shade proofing is really precise. Any troubles with shade will certainly show up on the proof, and therefore it will certainly be feasible to change it prior to printing the entire run.

Our 24hr Media Statements

Digital printing, on the various other hand, requires marginal configuration. There are much less pre-press procedures, so the preliminary arrangement time is significantly decreased. Consequently, turn-around is visibly much faster. Your order can be processed as soon as you submit it. This is fantastic when you are in a hurry to get your published products.

This means even more requests for electronic on-demand print manufacturing. Every client values an individualized message. Affordable, smaller sized sets enable organizations to customize each order.

Digital printing is the ideal selection for variable information printing, like personalized codes and addresses on straight mail. With electronic printing, it is less problematic to make last-minute changes to your design.

Indicators on 24hr Media You Need To Know

There is likewise no need to cleanse the plates after printing. The advantages of digital printing consist of that there is no waste from extra or remaining ink, paper, or chemicals due to the fact that only what's needed obtains printed. - for really brief runs, electronic printing is the way to go, undeniably.

Gone are the days of complex arrangements and lengthy turn-around times - digital printing has actually changed the print industry. The printing world has actually come a lengthy method considering that the days of Gutenberg's printing press. The brand-new typical is structured procedures and cost-efficient services for publishing onto practically anything you can think about.

Report this page